Blog

What Is M390 Steel? A Complete Guide to M390 Knife Steel

M390 steel is one of the most popular premium knife steels used in high-end folding knives and everyday carry (EDC) blades. It’s known for excellent edge retention, outstanding corrosion resistance, and refined cutting performance, which is why many enthusiasts consider it a top-tier “super steel.”

In this guide, we’ll explain what M390 steel is, how it’s made, its pros and cons, how it compares to other knife steels, and whether it’s the right choice for your needs.

Inhaltsübersicht

What Is M390 Steel?

M390 is a powder metallurgy stainless steel produced by Böhler-Uddeholm, a well-known Austrian steel manufacturer. Although it was originally developed for industrial cutting tools and molds, its performance characteristics made it extremely popular in the knife industry.

Because of its advanced composition and manufacturing process, M390 is commonly classified as a super steel.

Why M390 Steel Is Special

- Extremely high wear resistance

- Excellent corrosion resistance

- Long-lasting edge retention

- Fine, uniform grain structure

M390 Steel Composition

The performance of M390 steel comes from its carefully balanced chemical composition:

- Carbon (~1.9%) – Increases hardness and edge retention

- Chromium (~20%) – Provides strong corrosion resistance

- Vanadium (~4%) – Improves wear resistance

- Molybdenum (~1%) – Adds strength and toughness

- Tungsten (~0.6%) – Enhances edge stability

With proper heat treatment, M390 typically reaches 60–62 HRC, making it very hard while still maintaining usable toughness.

How Is M390 Steel Made?

M390 is manufactured using powder metallurgy (PM) technology rather than traditional steel casting.

Powder Metallurgy Explained

- Molten steel is atomized into fine powder

- The powder is compressed under extreme pressure

- It is sintered into a solid billet

Benefits of Powder Metallurgy

- Even carbide distribution

- Fewer weak points

- Better consistency and edge stability

This process is a major reason M390 outperforms many conventional stainless steels.

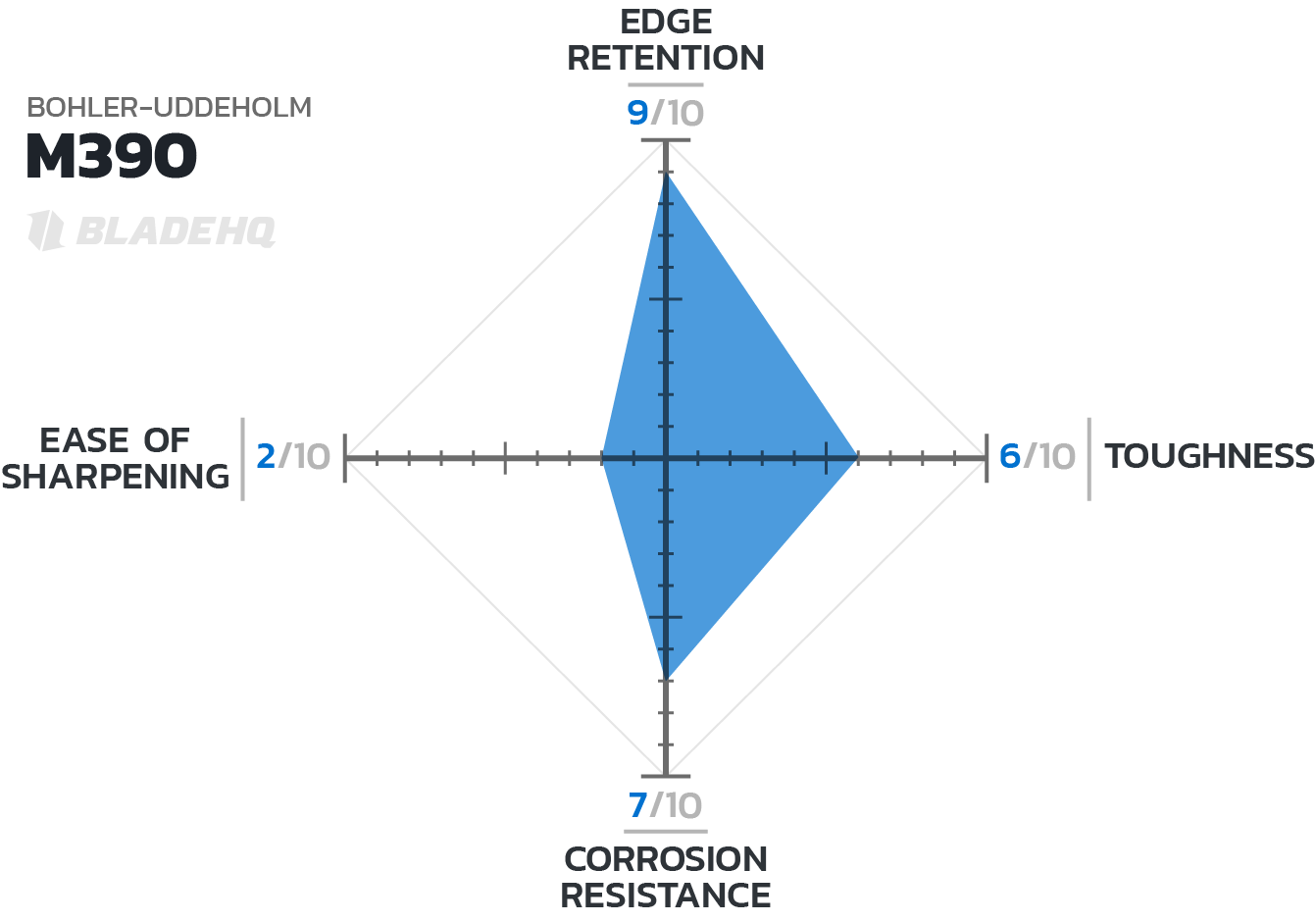

M390 Steel Performance Overview

Edge Retention

M390 offers exceptional edge retention, meaning it stays sharp for a very long time—even with regular use.

Corrosion Resistance

With approximately 20% chromium, M390 is highly stainless and performs well in humid, wet, or coastal environments.

Wear Resistance

Thanks to its high vanadium content, M390 resists abrasion extremely well, making it ideal for slicing tasks.

Toughness

M390 has moderate toughness. It’s durable enough for everyday cutting but not designed for heavy impact or prying.

Ease of Sharpening

Because of its hardness and wear resistance, M390 is difficult to sharpen compared to mid-range steels. Diamond or ceramic stones are recommended.

Pros and Cons of M390 Steel

Advantages

- Excellent edge retention

- Outstanding corrosion resistance

- High hardness potential

- Premium look and performance

- Long service life

Disadvantages

- Expensive compared to standard steels

- Harder to sharpen

- Not ideal for extreme hard-use tasks

M390 Steel vs Other Popular Knife Steels

M390 vs S30V

- M390 holds an edge longer and resists corrosion better

- S30V is easier to sharpen and more affordable

Verdict: M390 for performance, S30V for value

M390 vs S35VN

- M390 offers better edge retention

- S35VN provides improved toughness and easier maintenance

Verdict: Depends on your priorities

M390 vs MagnaCut

- MagnaCut offers superior toughness with excellent corrosion resistance

- M390 still excels in edge retention

Verdict: MagnaCut for hard use, M390 for slicing and EDC

M390 vs Elmax

These steels are very similar in composition and performance.

Verdict: Heat treatment matters more than the steel name

Common Uses of M390 Steel

M390 is widely used in:

- Premium folding knives

- High-end EDC knives

- Custom and mid-tech blades

- Industrial cutting tools

Knife Brands That Use M390

- Benchmade

- Microtech

- Zero Tolerance

- WE Knife

- LionSteel

- Böker

Is M390 Steel Good for Everyday Carry?

Yes. M390 steel is excellent for EDC, especially if you want:

- A knife that stays sharp for a long time

- Minimal maintenance

- Strong rust resistance

However, users who sharpen frequently or need maximum toughness may prefer other steels.

How to Sharpen M390 Steel

For best results:

- Use diamond or CBN stones

- Avoid cheap pull-through sharpeners

- Finish with a light strop

Recommended sharpening angle: 15–20° per side

Is M390 Steel Worth It?

M390 knives are usually more expensive due to:

- Advanced powder metallurgy production

- High alloy content

- Premium market positioning

If you value edge retention, corrosion resistance, and long-term performance, M390 is absolutely worth the price.

Frequently Asked Questions About M390 Steel

Is M390 steel stainless?

Yes. M390 is highly stainless due to its high chromium content.

Is M390 better than D2?

Yes. M390 offers better corrosion resistance, edge retention, and consistency.

Can M390 steel rust?

It is very rust-resistant, but neglect or prolonged saltwater exposure can still cause corrosion.

Who makes M390 steel?

M390 is produced by Böhler-Uddeholm in Austria.

Final Thoughts: Is M390 Steel Good?

M390 steel is one of the best knife steels available today. It combines excellent edge retention, strong corrosion resistance, and premium performance. While it’s not the toughest steel on the market, it’s an outstanding choice for EDC knives and high-end folding blades.

If you want a knife that stays sharp, resists rust, and feels premium, M390 steel is hard to beat.